Case Study - Additive Manufacturing

Streamline your entire process from Quoting through Production Schedule Management!

1. Background

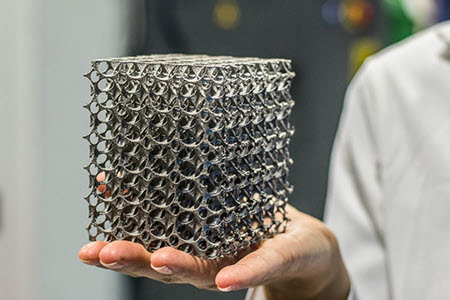

The company in this case study provides additive manufacturing services to a broad cross-section of customers.

In addition to the part manufacturing itself, it also offers services such as: machining, sanding, painting.

Because of these value-add services, the company is firmly in the build-to-order business - where each quote and order is unique.

This is distinctly different from a company that makes stock keeping unit (SKU) like products such as: chairs, consumer products, etc.

SKU products are not configured – in other words customers are not choosing options.

This company has not yet explored nor invested in the setup of and ERP software. Like many small businesses, it is running the business using Microsoft Office – Excel and Word.

Excel is used for quoting, orders, managing production orders, and other data.

The company in this case study provides additive manufacturing services to a broad cross-section of customers.

In addition to the part manufacturing itself, it also offers services such as: machining, sanding, painting.

Because of these value-add services, the company is firmly in the build-to-order business - where each quote and order is unique.

This is distinctly different from a company that makes stock keeping unit (SKU) like products such as: chairs, consumer products, etc.

SKU products are not configured – in other words customers are not choosing options.

This company has not yet explored nor invested in the setup of and ERP software. Like many small businesses, it is running the business using Microsoft Office – Excel and Word.

Excel is used for quoting, orders, managing production orders, and other data.

2. Problem

The company has recognized that the significant manual effort in scheduling requires they do something different in how they run the business. One solution explored is an ERP software. This is a big investment and change in processes for employees. ERP software is designed to have an assembly (top level) part number for every line item (quote or order). Below this assembly part number is a unique production router and bill of materials. Using an ERP for a configured product to create a quote with 5 line items would require creation of: 5 assembly part numbers, 5 production routers and 5 bills of material (BOM). This is made somewhat easier by duplicating and then editing an existing router and BOM. The router is still a challenge however, because the process time for each of the production steps would need to be estimated and updated.

A. BOM

The cost of the material is a function of:

- Material

- Volume (cubic inches). The volume is a function of:

- Length

- Width

- Height

B. Router

Switching focus to the router, the possible tasks are:

- MIXING

- BUILD

- COOLDOWN

- BREAKOUT

- POSTCURE

- WASH

- INSPECTION

- SANDING (Y/N)

- BONDING (Y/N)

- BLASTING (Y/N)

- PAINTING (Y/N)

3. Solution

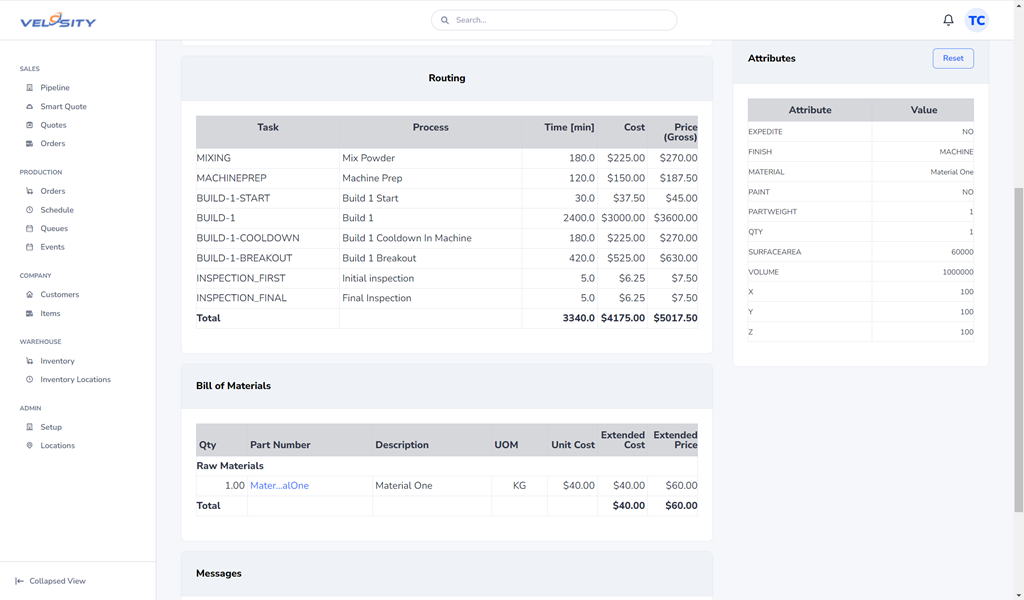

Velosity solves this problem uniquely. Velosity does not require the creation of: 1) assembly part numbers, 2) routers, 3) bill(s) of material. Instead, Velosity generates the router and BOM dynamically based on the product features (attributes) selected.

- Attributes (Product Specific)

- Items

- Tasks (Process Steps)

- Rules (Product Specific)

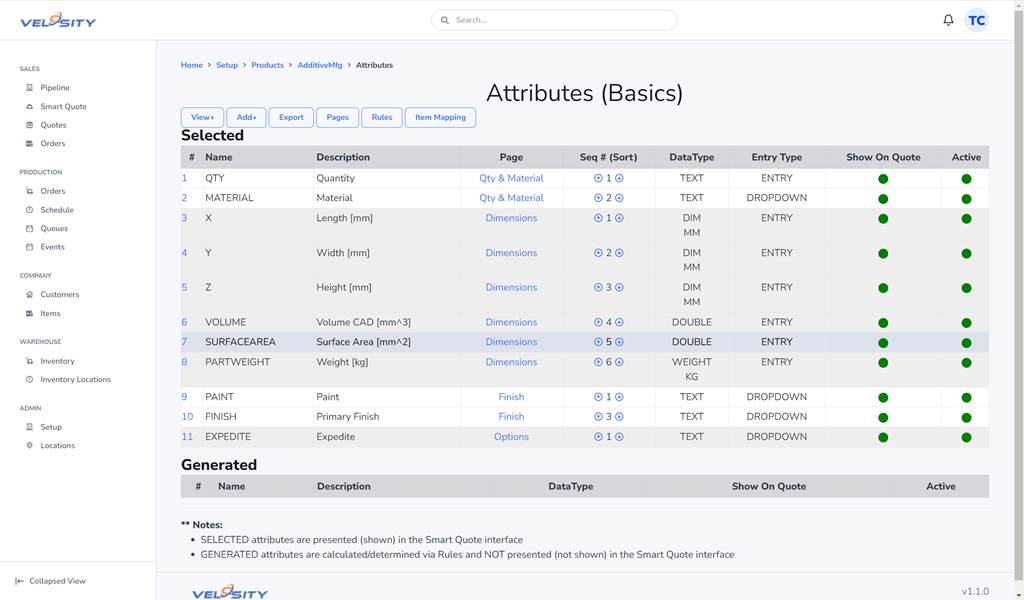

A. Attributes

The attributes that the user would select are shown below:

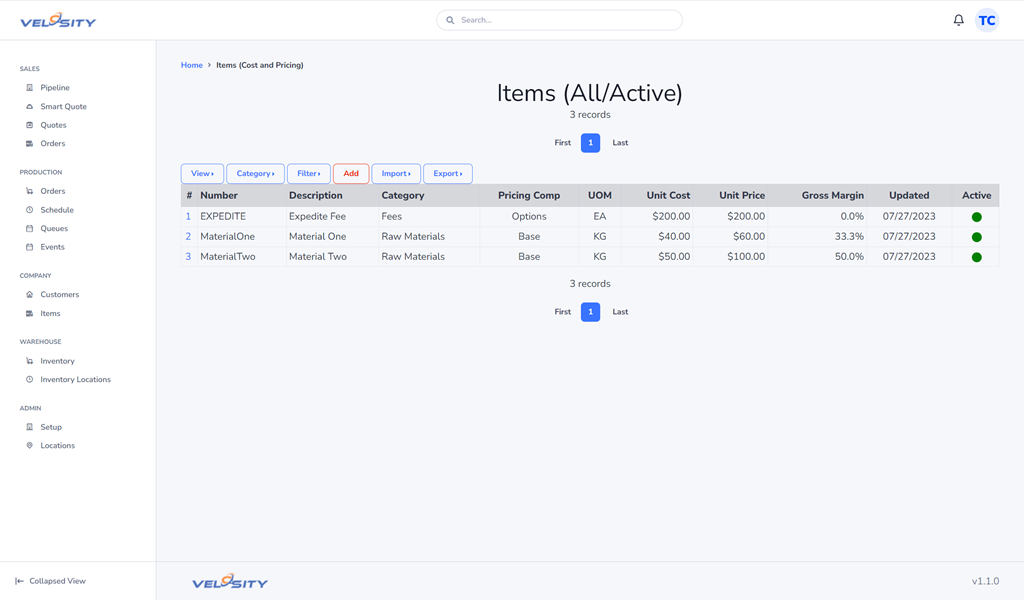

B. Items

The items that are added by the Rules or Item Mapping are shown below:

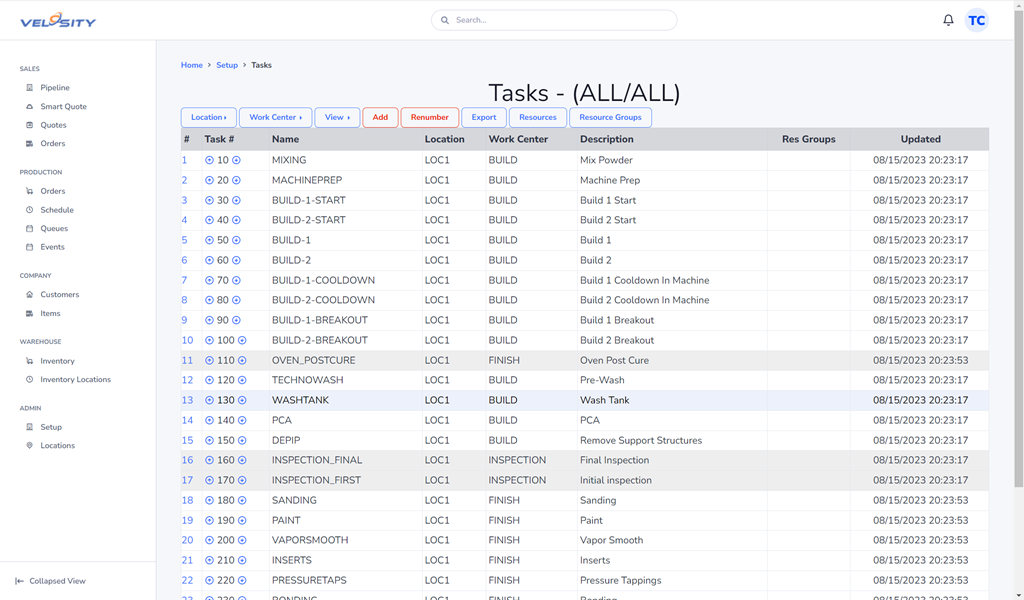

C. Tasks

The process steps (tasks) for this company are many and are beyond the just the 3D printing processes. Shown below are the Tasks as setup in Velosity

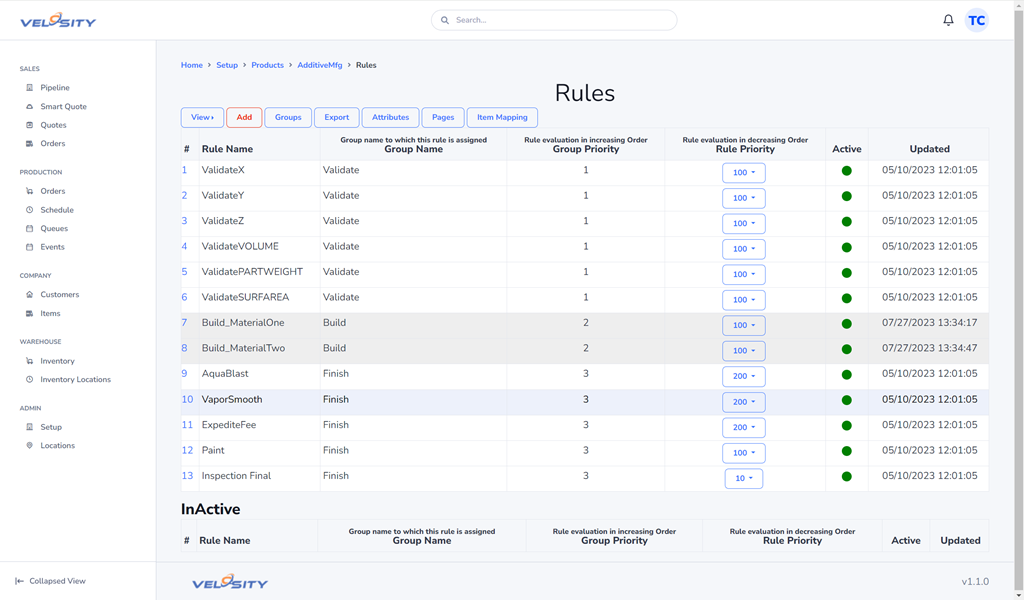

D. Rules

The rules that are evaluated to generate the router, BOM, cost and pricing are shown below:

4) Results

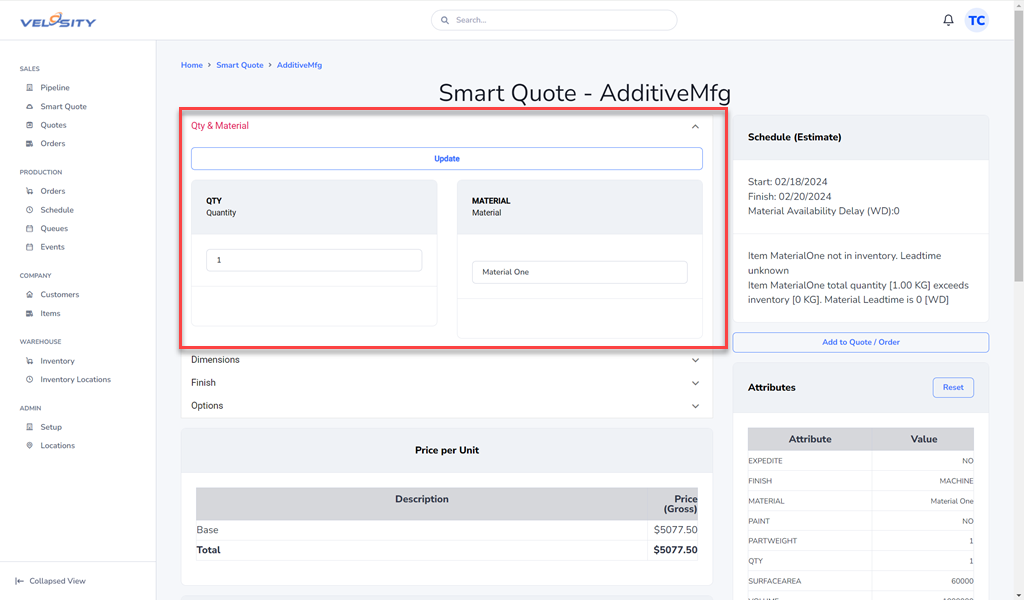

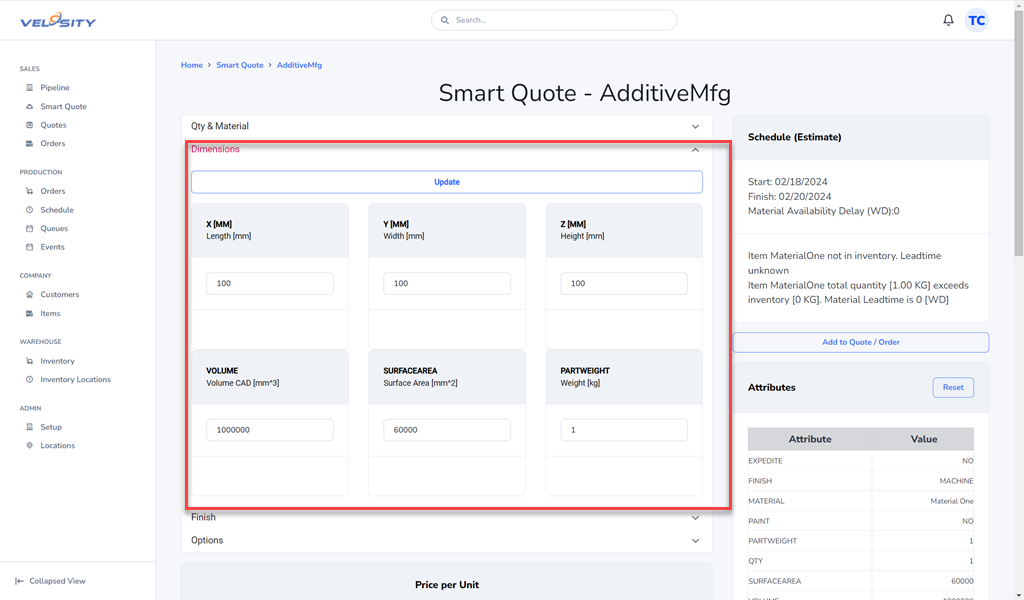

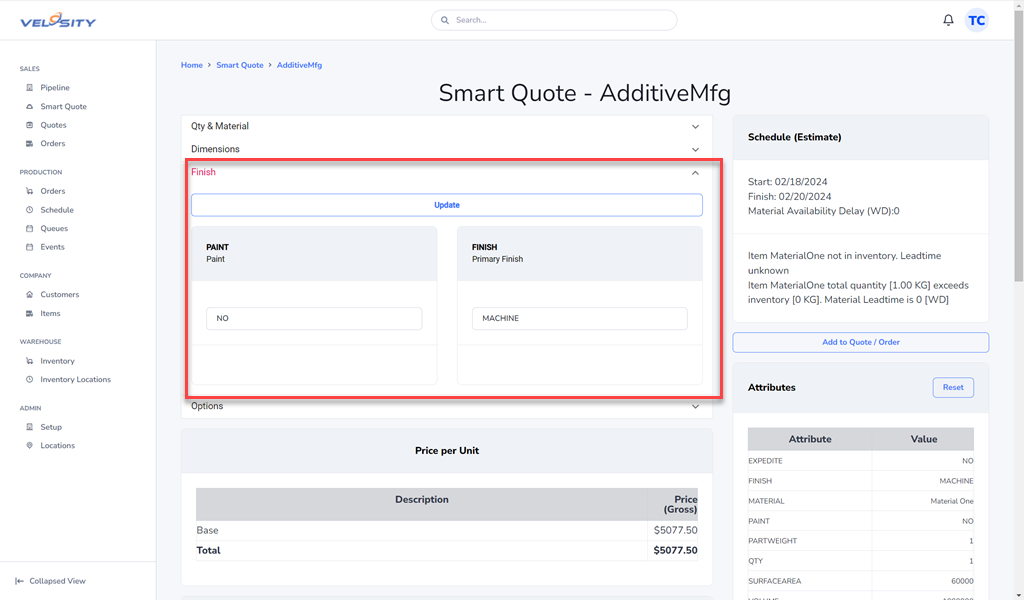

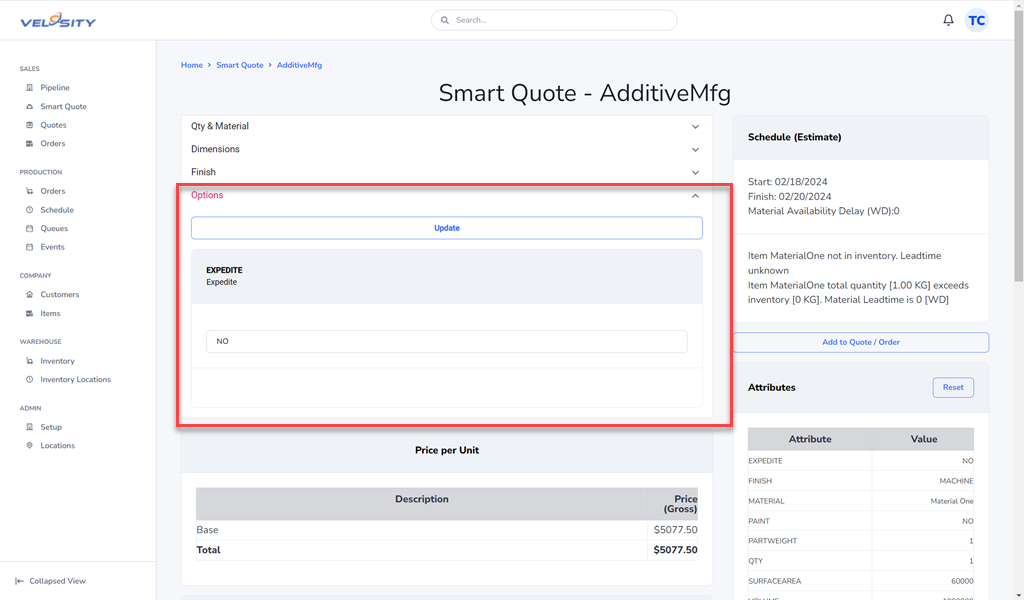

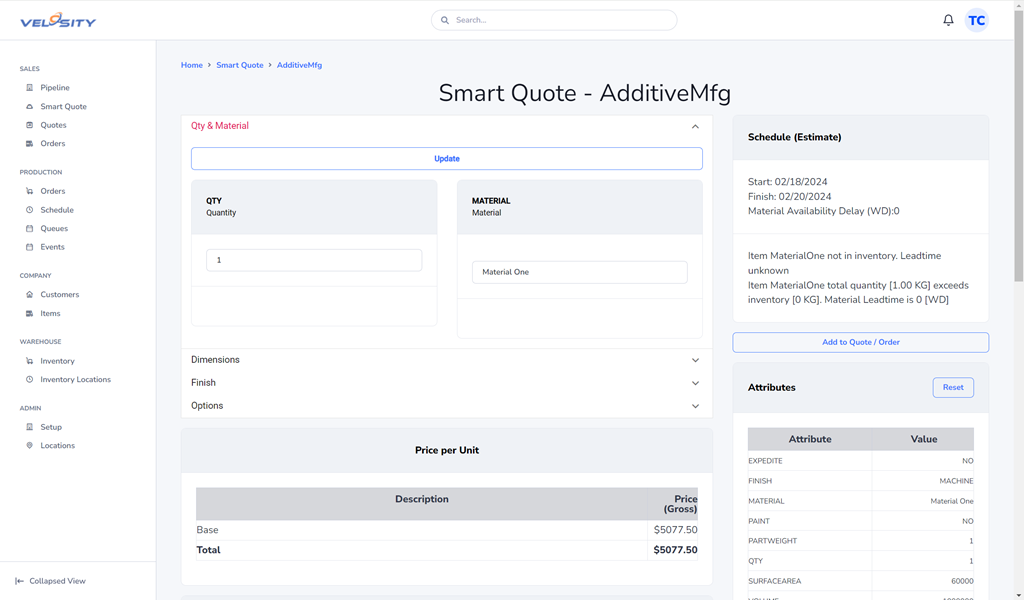

With SmartQuote, your sales team is able to generate quotes and orders in under sixty seconds - without creating any routers or BOM!), like this:

5. Conclusion

Velosity transformed the quote and order management processes for this company compared to Excel being used previously. It also gained the ability to quickly lookup historical quotes and orders. The company is next looking to use the production order and scheduling functionality in Velosity to reduce the effort required for scheduling, completion date visibility. Part of this improvement will be the rollout of rugged tablets at each workstation to provide shop personnel with visibility of current and upcoming production orders along with production order time clocking. The time clocking will provide data to improve the time calculation in the router steps – leading to new insights about efficiency and pricing vs value delivered to their customers.